Production Engineers

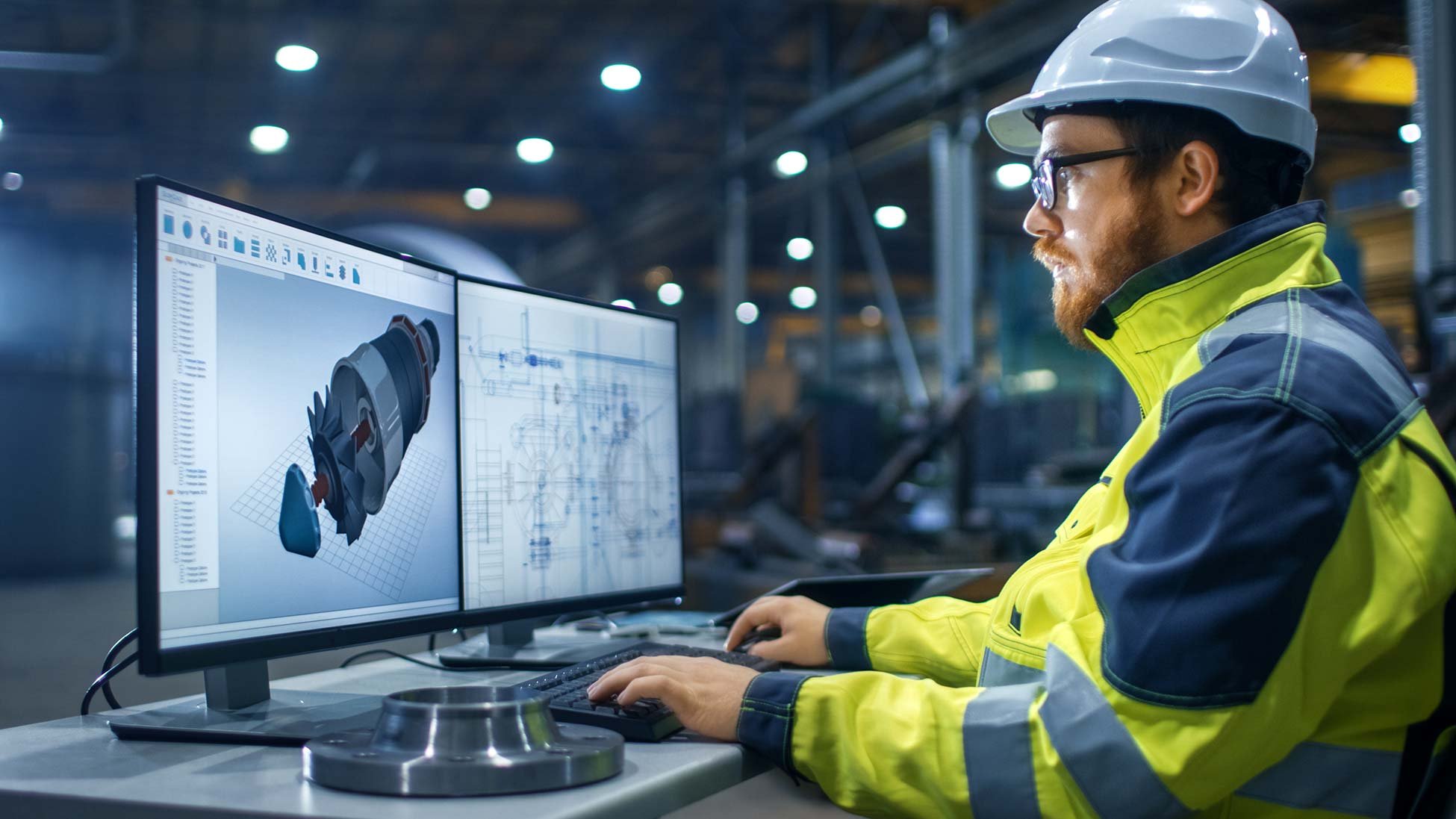

Production engineers are highly skilled and independent critical thinkers with proven knowledge of computer-aided design (CAD) software and Failure Mode Effect Analysis (FMEA). They are eager to improve lean production processes while working alongside innovative engineering teams within the industrial or commercial sectors.

Production engineers search for ways to optimise production processes while working together with diverse and highly skilled team members in design, manufacturing, and/or supply chain roles. Working in production systems engineering, the engineers are involved in product manufacturing from end-to-end requiring both flexibility and proactiveness. Production engineers must be detail oriented while never losing focus of the big picture.

Production systems engineering expertise is crucial to product manufacturing in a broad range of industries. Some of the popular industries right now include software, pharmaceuticals, automotive, aerospace, renewable energy, food and fast-moving consumer goods (FMCG), among others.

In the pharmaceutical industry for instance, a production engineer may be responsible for minimising bottlenecks in the production of high-quality medicines. In the aerospace sector, an engineer in production may oversee the assembly of an airplane engine.

In fact, all the products that enter our homes have been carefully thought out and planned out by a production engineer at one point in the lifecycle.

Common production engineering responsibilities

In the role as production engineer, responsibilities require performing a range of important tasks to create, test and implement embedded software systems. Responsibilities and tasks may include:

- Supervising the entire manufacturing process to optimally deliver the highest quality on time;

- Analysing and diagnosing production line issues and providing recommendations to continuously improve the processes and workflow;

- Staying updated on the latest advancements in production and engineering, lean methodology and system approaches;

- Creating and managing production schedules and budgets to ensure smooth production and resource allocation at minimal cost in line with KPIs;

- Collaborating with team members, including engineers, R&D, logistics specialists and project managers, to develop comprehensive production plans;

- Providing strategic inputs to enhance existing programs or systems, and to develop new ones in line with best practices;

- Managing and lead team members, providing coaching support and motivating them to operational success;

- Safeguarding team members by establishing and implementing safety protocols;

- Ensuring quality assurance through compliance with relevant production requirements, codes, and certifications, and in line with customer needs and demands;

- Liaising with a multitude of stakeholders both inside and outside of the organisation such as other internal departments, customers, and suppliers to communicate market or production changes and business solutions.

Qualifications for a production engineer

At a minimum, production engineers should possess a Bachelor’s degree in Mechanical Engineering, Industrial Engineering, Electrical Engineering, Physics, or a related technical field.

Additional qualifications include:

- Solid IT skills and interest, with proven experience using CAD software and other control systems software;

- Experience with process mapping, optimisation, modelling, and performance analysis;

- Knowledge of supply chain management, logistics, quality management, and operations;

- Keen attention to detail with big picture strategic thinking capabilities;

- Strong verbal and written communication skills to collaborate effectively with people in diverse roles and translate technical information to non-technical team members.

- If production engineers seek to become a production engineering manager, this requires at least 3 to 4 years of direct management experience.