Hydrogen propulsion is the use of hydrogen to create self-sufficient energy. Something called a fuel cell is built into the car and uses the chemical energy of hydrogen to produce electricity. When a simulated chemical reaction happens in the fuel cell, hydrogen breaks off an electron and sends that electricity to the car's engine to generate propulsion (moving forward). In addition to battery technology, this technology is an essential pillar in the mobility transition. The first hydrogen-powered cars are already in use. However, there are several challenges to overcome before large scale production, such as emission-free hydrogen production.

Overview of content

How does a hydrogen propulsion work?

How is hydrogen produced?

What challenges does the automotive industry face in using hydrogen technology?

What opportunities does hydrogen technology offer the automotive industry?

How does hydrogen propulsion ensure greater sustainability?

Which professions are involved in the development of hydrogen propulsion?

How does a hydrogen propulsion work?

The key to hydrogen propulsion is the reaction happening between hydrogen and oxygen. This process is known as reverse electrolysis and occurs in the fuel cell. The result of this reaction is heat, water and electric energy. The hydrogen comes from a tank built above the fuel cell in the vehicle. Electricity travels from the fuel cell to the engine while water vapour escapes through the exhaust. In simplified terms, it's a self-sufficient energy fueled car that does not require a storage system like a battery, all while being locally emission-free.

One crucial difference between hydrogen fuel cell cars and alternative electric vehicles is - Hydrogen cars produce electricity themselves.

How is hydrogen produced?

Since hydrogen is in a particular form, it cannot be mined or extracted like other fuels. Instead, it's split from more complex molecules. Currently, hydrogen production is through the so-called reformation of natural gas. Adding water vapour to the natural gas. Producing a chemical reaction, the products of which are CO2 and hydrogen.

The actual hydrogen propulsion does not produce any greenhouse gas emissions, but natural gas-based production does. The latter is still dependent on energy carriers - in this case, natural gas. Hydrogen produced in this way is called grey or black hydrogen.

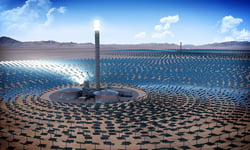

In contrast, so-called green hydrogen is produced entirely without fossil fuel, raw materials. It is, therefore, seen as the energy carrier of the future, made by electrolysis. In this process, the hydrogen is separated from the water with the help of electrical energy and stored. The electricity needed for this comes from renewable sources such as wind or solar energy. The only waste product is oxygen, which can either be used or released into the environment, without any consequences.

What challenges does the automotive industry face in using hydrogen technology?

Both the actual hydrogen propulsion and hydrogen production have long been technically possible. The challenge is to make this technology applicable on a large scale. Sustainability means it must be possible to produce and transport sufficient green hydrogen. The restricting factor is the limited potential for the expansion of renewable energies. Moreover, electrolysis is a relatively expensive process.

The production of fuel cells is also expensive, as it requires platinum - a metal that is known to be more valued than gold, subsequently leading to research on how to reduce the need for platinum and recycle the material. Copper, a much more affordable material, is being investigated to help produce a more affordable fuel cell. In addition, a sufficient network of hydrogen filling stations must be established.

What opportunities does hydrogen technology offer the automotive industry?

Hydrogen technology offers the automotive industry the opportunity to reduce its CO2 emissions and eventually eliminate them. After all, this form of propulsion enables emission-free driving. Unlike electric mobility, the installation of heavy batteries is obsolete and hydrogen-powered vehicles have more range.

Refuelling a car takes between three and five minutes, significantly faster than recharging an electric vehicle. Hydrogen technology is more accepted, by the public, as a sustainable technology of the future. More so than electric mobility, which is still very controversial, although the latter will become much more widespread in the next ten years.

How does hydrogen propulsion ensure greater sustainability?

In the form of green hydrogen, it is a highly sustainable, emission-free propulsion technology. The raw materials used are water and electricity from renewable sources, available in virtually unlimited quantities. If they rectify the problem for platinum for fuel cells by recycling and alternative metals, environmentally harmful mining of platinum is no longer necessary and the materials used are recycled. Due to its environmentally friendly properties, hydrogen technology is considered the fourth pillar of the energy transition, alongside renewable energies, energy efficiency and electrification.

In addition to the use of hydrogen for passenger cars, truck transport is also a potential area of application for hydrogen propulsion, as is public transport in the form of hydrogen buses. Overall, hydrogen technology eliminates any problems associated with battery production, such as the environmentally harmful extraction of raw materials or disposal. The fuel cell's high efficiency of up to 65 per cent, which is about twice that of the internal combustion engine, also contributes to sustainability.

Which professions are involved in the development of hydrogen propulsion?

First of all, mechanical and electrical engineers are involved in the development of hydrogen propulsions, and they have the appropriate specialisation. Companies and universities are increasingly offering further training in hydrogen technology and fuel cells. Specialists in electrochemistry and electroplating are also significantly involved in the development and construction process of this technology. Hydrogen mobility also offers attractive job opportunities for specialised chemists and physicists. For later installation and maintenance, professions from the fields of assembly, construction and service are in demand, whereby a corresponding focus on the field of hydrogen technology should also be present here.